This is an idea suggested by George Kujanski on the Performance Years Board in a thread started by PMDRACER.

This basically applies to the newer 11 bolt water pump.

The older water pump is designed differently and may not apply.

Thread Link

If you are having problems with overheating and have tried just about everything, you might want to try this.

George Kujanski wrote:

I've got a few words on that subject: I don't have a stamped impeller, but I do know that pump efficiency is directly related to the clearance between the divider plate and the vanes. If your clearance, (regardless of cast or stamped) is more than say, .060", YOU ARE THROWING AWAY COOLING EFFICIENCY. I tweaked mine from about .250" down to about .100" and it made a drastic change in my engine temps with no other changes. You can spend money on big radiators, electric fans, magic cooling fluid, yadda,yadda, but if you are running a large clearance all the other stuff is a band aid. Do the clearnace thing first, then go from there. Cost is a few bucks for a gasket. Not only that, hot start problems went away too...a possible side benefit.

11 bolt water pump. 1. Water pump NAPA pump part #: DPW1301280 2. New Sleeve assembly. Can still be ordered through GM Part # 9796347 3. Spacer plate clearence mod Try to get the clearence as close as possible. .025" or under

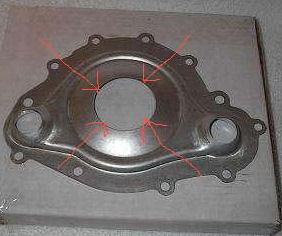

Here is a pic of a cast impeller:

Here is a pic of a stamped impeller:

I took the pump & put it upside down on the bench (obviously you have to take the pump off) put the gasket on it then the divider plate. Measure the clearance between the pump side surface of the plate and the edge of the vanes. This should be made as close as possible. I used a hammer to carefully bend the circumference of the hole of the divider plate towards the vanes. The suction of the pump is thru the center hole, and the pressure side is around the tips of the vanes. Too much of a gap between the plate and the vanes and the pump tends to draw coolant from the pressure side instead of from the center hole (which is plumbed to the radiator and the hot side of the block). That's why minimizing this leakage path improves flow thru the engine and thru the radiator (when the thermostat is open).

A while back i also received correspondence from Geoff in Australia regarding this subject. I'll paste it in here:

George, I saw your comment about closing the gap between the impeller & the divider plate. I went even further than you did. Using some scraps of stainless steel exh pipe, I cut strips about 1/4'' wide & the same length as the impeller blade & brazed them onto the back of the blades. I did one blade at a time, & carefully ground the extension a little bit at a time until the impeller would rotate without touching the plate. I then did the next blade until all 8 were done. Clearance between blades & plate was 0.030'' at most. What a difference! This pump cools better than the Flow Kooler. Geoff, Australia

Old Goat 67 (also from PY board) tried the fit before bending the divider plate, and was surprised to see that the Cardone pump had vanes that were 3/16 “ taller than the old one. The divider plate would only require minor tweaking. Will attach two photos showing the difference. Old pump first, new one next.

New pump, check the clearance. No difference in plate tweaking.